Why choose Ntensify™ ?

Our design brings three main benefits to your mRNA program:

- De-risked development: The Ntensify™ process has been successively optimized over hundreds of Upstream and Downstream reactions with 18 different constructs varying in length from around 1,000 nucleotides (mRNA) to 11,000 nucleotides (samRNA). Today, we dare to say that Ntensify™ delivers above-average performance both in yield and quality, fit for various types of RNA constructs.

- Speed to market: Ntensify™ accelerates development during the discovery phase with high throughput candidate screening and through its ability to produce micrograms up to multiple kilograms of RNA drug substance without months of scale-up.

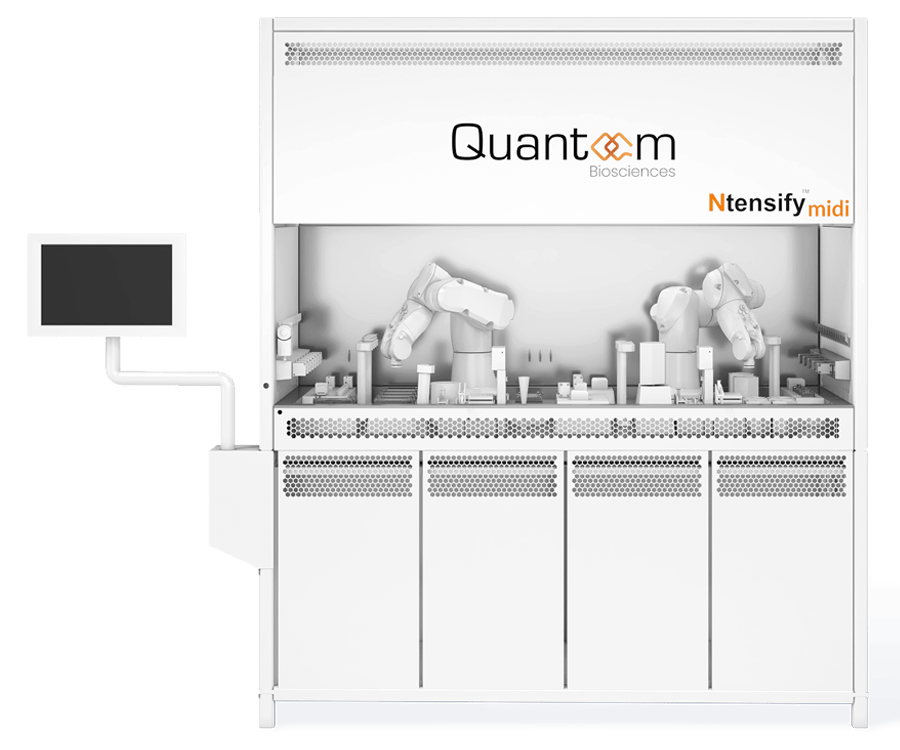

- Cost-effectiveness: our Ntensify™ Production Technologies give developers significant savings. Our intensification and chaining principles ensure that Ntensify™ has a very small footprint and the ability to handle smaller volumes than conventional approaches. This reduces size of the production facility and the capital required as well as lowering operating costs due to smaller volumes.

Key features

No scale-up needed (pre-)clinical development is already at the final scale, which accelerates your process & product development

Single small footprint system that integrates all process steps – no need to invest in a suite of equipment

Generic process* that is adaptable to your specific RNA construct both for transcription and purification with polishing options

Reduced CoGs thanks to minimal labor & RNA expertise required

In vivo validated with multiple RNA constructs to de-risk your product development

Practical and flexible range of equipment to fit to all phases of a project, from drug discovery to commercial production

*We have developed an optimized in-vitro transcription method to obviate the need for downstream dsRNA clearance while improving reaction yield and reducing consumption of capping reagent without sacrificing capping yield. Our new process template has proven successful for different RNA constructs, requiring only minimal customization. Fewer purification steps are required while still guaranteeing high quality.

Key features:

No scale-up needed (pre-)clinical development is already at the final scale, which accelerates your process & product development

Single small footprint system that integrates all process steps – no need to invest in a suite of equipment

Generic process* that is adaptable to your specific RNA construct both for transcription and purification with polishing options

Reduced CoGs thanks to minimal labor & RNA expertise required

In vivo validated with multiple RNA constructs to de-risk your product development

Practical and flexible range of equipment to fit to all phases of a project, from drug discovery to commercial production

*We have developed an optimized in-vitro transcription method to obviate the need for downstream dsRNA clearance while improving reaction yield and reducing consumption of capping reagent without sacrificing capping yield. Our new process template has proven successful for different RNA constructs, requiring only minimal customization. Fewer purification steps are required while still guaranteeing high quality.

Contact Us

Please complete the form below for any commercial, partnering, media, press, or general inquiries.

If you need to contact our customer service team, please click on the button below.